The introduction of Continuous Integration (CI) and Continuous Deployment (CD) practices in robotics is a game-changer, driving efficiency and reliability in the development lifecycle of robotic systems. While CI/CD has been a cornerstone of modern software engineering, its application to robotics presents unique challenges due to the physical nature of robots, hardware-software integration, and the complexity of real-time systems.

This article explores the key concepts of CI/CD, highlights its challenges in the context of robotics, presents an overview of current tools and technologies, and offers practical guidelines for successfully implementing CI/CD in robotic system development.

Additionally, it discusses the significant role of simulation, automated testing, and hardware-in-the-loop (HIL) testing in achieving continuous integration and deployment for robotic systems. The aim is to provide insights into how these practices can be applied to improve collaboration between teams, reduce deployment gaps, and ensure system reliability in the dynamic environment of robotics.

1. Introduction

Continuous Integration (CI) and Continuous Deployment (CD) are key practices in modern software development that have revolutionized how developers manage, test, and deploy applications. CI refers to the practice of automatically integrating code changes into a shared repository several times a day, enabling teams to detect issues early and streamline the development process. CD on the other hand automates the release of new software versions to production, enabling faster and more frequent deployments.

In the context of robotics, CI/CD has become a critical enabler for accelerating the development and deployment of robotic systems. The field of robotics combines hardware and software, with robots interacting with the physical world through sensors, actuators, and controllers. These systems are inherently complex, and any software update or modification must be tested not only for functionality but also for its impact on the physical performance of the robot. Therefore the need for automation in both software and hardware testing, as well as rapid deployment, is critical to ensuring reliability, safety, and performance (1).

This article explores the role of CI/CD in robotics development, discusses the unique challenges that arise when applying these practices to robotics, and highlights how various tools and techniques can be utilized to implement CI/CD in this domain. By examining case studies, industry practices, and emerging tools, we aim to present a roadmap for successful implementation of CI/CD in robotics.

2. Overview of CI/CD in Software Development

Before delving into the specifics of CI/CD in robotics, it is important to first understand the core principles of CI/CD and their benefits in software development.

2.1 Continuous Integration (CI)

Continuous Integration is a development practice where code changes are integrated into a central repository frequently, usually several times a day. Automated testing is triggered each time new code is committed to the repository. CI aims to detect bugs or integration issues early in the development process, preventing the accumulation of technical debt.

The main benefits of CI include:

- Early Detection of Bugs: By integrating code frequently, teams can quickly identify and fix issues before they grow into larger problems.

- Improved Code Quality: Frequent testing and integration lead to higher code quality as potential errors are caught early.

- Faster Feedback: Developers receive rapid feedback on the impact of their changes, enabling them to adjust their approach quickly.

- Better Collaboration: Since team members are encouraged to integrate frequently, CI fosters better collaboration and communication between developers.

2.2 Continuous Deployment (CD)

Continuous Deployment extends CI by automating the release of software changes to production. Once the software passes all automated tests in the CI pipeline, it is automatically deployed to production, making the software available to users without manual intervention.

Benefits of CD include:

- Reduced Risk: By deploying changes incrementally and frequently, the risk of large-scale failures is reduced, as issues can be identified and addressed with a short turnaround time.

- Faster Time-to-Market: Automated deployment reduces the time it takes to release new features or bug fixes, ensuring that changes are delivered to users quickly.

- Consistency: Automated deployment ensures that the release process is consistent, eliminating human error and ensuring that each deployment follows the same steps.

- Increased Efficiency: With minimal manual intervention required, teams can focus more on developing new features rather than managing deployments.

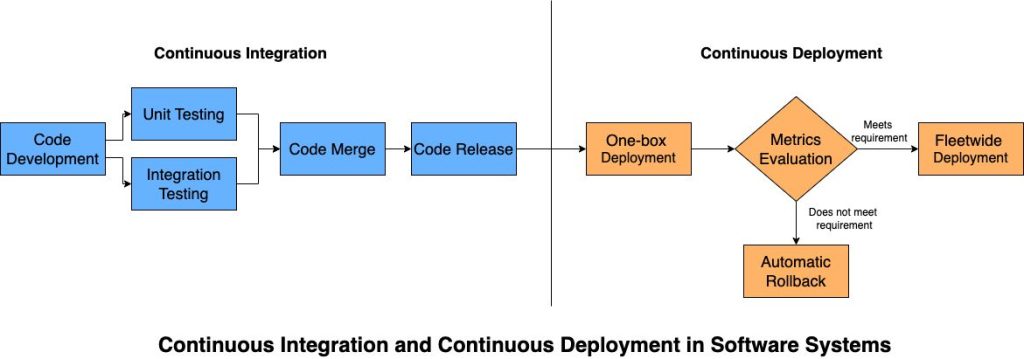

2.3 The CI/CD Pipeline

The CI/CD pipeline is a sequence of automated processes that enables the efficient and reliable integration, testing, and deployment of code. A typical CI/CD pipeline involves several stages:

- Code Commit: Developers commit code to the central repository.

- Build: The system automatically builds the software, checking for errors or issues in the code.

- Test: The software undergoes automated unit, integration, and sometimes system tests to verify its correctness.

- Deploy: The software is deployed to a testing or production environment.

- Monitor: Continuous monitoring tools ensure the system is operating as expected.

In a typical software application, the CI/CD pipeline is fully automated, ensuring that every change is tested and deployed quickly and reliably. An illustration of a CI/CD pipeline for a software system is shown in Figure 1 above.

3. Challenges in Enabling CI/CD in Robotics

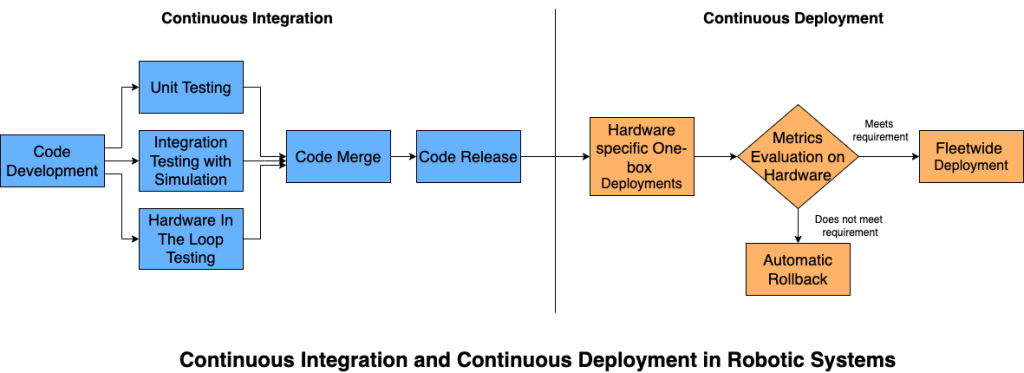

While CI/CD practices have proven effective in software development, applying them to robotics introduces several unique challenges. These challenges arise due to the complexity of the hardware-software interaction, real-time performance requirements, and the need for rigorous testing in both virtual and real-world environments (2). This section discusses the high level challenges and explains how each of the challenges are unique to robotics.

3.1 Hardware and Software Integration

Robotics systems require tight integration between software and hardware components. Unlike traditional software applications that run on standard computing platforms, robotic systems interact with the physical world through sensors, actuators, and controllers. This creates several challenges for CI/CD in robotics:

- Hardware-Specific Dependencies: Robots often rely on specific hardware configurations, and software changes can have direct physical consequences. Ensuring that software updates do not negatively impact the robot’s hardware performance is critical.

- Embedded Systems: Many robots are powered by embedded systems with limited computing resources. These systems may not support the full range of development tools or CI/CD automation available for desktop or cloud-based systems.

- Diverse Platforms: Robots often operate across a wide range of hardware platforms, such as mobile robots, drones, industrial arms, and humanoid robots. CI/CD pipelines must be flexible enough to handle different hardware setups and configurations, often requiring custom solutions for each version.

3.2 Real-Time Systems

Many robotic applications require real-time performance, where software responses must be executed within strict time constraints. Ensuring that CI/CD pipelines do not disrupt real-time operations is a major challenge:

- Latency and Timeliness: Real-time robotic systems must guarantee that software updates do not introduce unacceptable delays or interfere with critical operations. CI/CD pipelines must be optimized to minimize latency, ensuring that real-time constraints are met.

- Safety and Robustness: Robotic systems, especially those operating in safety-critical environments (e.g., healthcare robots, autonomous vehicles), require rigorous testing to ensure that software changes do not compromise safety. CI/CD practices must be tailored to ensure the integrity and reliability of these systems under real-world conditions.

3.3 Testing and Simulation

The traditional approach of testing software in isolation does not work in robotics, where testing must also account for physical interactions with the environment. Furthermore, real-world testing can be expensive and time-consuming (3).

Simulation-Based Testing: To mitigate the cost and complexity of real-world testing, many robotics teams rely on simulation environments (e.g., Gazebo (4), https://gazebosim.org/home, Webots (5) – https://cyberbotics.com/ ). Simulations allow developers to test software changes in a virtual environment that mimics real-world conditions (6) – (13). However, the challenge lies in ensuring that simulation results accurately reflect real-world performance and in closing the gap between simulation and real world (14).

Hardware-in-the-Loop (HIL) Testing: In some cases, testing with actual robotic hardware is essential. HIL testing combines the benefits of simulation with real-world interaction, allowing robotic software to be tested on actual hardware while maintaining the flexibility of simulated environments. This approach can be used to validate complex robotic systems and ensure that software updates do not introduce errors or degrade performance.

3.4 Deployment and Rollback

The deployment process in robotics differs from traditional software systems because it must ensure that new software versions are compatible with both hardware and the operating environment. Additionally, rolling back deployments can be particularly challenging in the context of robotics.

Over-the-Air Updates: For mobile or field-deployed robots, over-the-air (OTA) updates allow new software versions to be deployed remotely. However, ensuring that these updates do not interrupt robot operations or lead to failure in the field presents a significant challenge.

Rollback Mechanisms: Unlike traditional software systems, which can be rolled back quickly in the event of a failure, robotic systems may require custom rollback mechanisms that account for both hardware and software components. Effective rollback strategies are essential to minimize downtime and ensure that robots can recover from failed updates.

4. Key Tools and Technologies for CI/CD in Robotics

To enable CI/CD in robotics, several tools and technologies can be employed to address the unique challenges posed by robotic systems. These tools support automation, testing, simulation, and deployment, making it possible to implement continuous integration and deployment effectively in robotics development.

4.1 CI/CD Platforms

The choice of CI/CD platform is one of the most important considerations when implementing automation in robotics. Some popular platforms used in the robotics industry include:

- Jenkins: Jenkins is a widely used open-source CI/CD tool that supports automation, building, testing, and deploying software. Jenkins can be extended with plugins for robotic-specific needs, such as ROS (Robot Operating System) integration or simulation testing.

- GitLab CI https://about.gitlab.com/solutions/continuous-integration/ : GitLab CI offers a robust and scalable CI/CD solution with features like version control, automated testing, and seamless integration with Docker and Kubernetes for deployment.

- CircleCI https://circleci.com/ : CircleCI provides fast and scalable CI/CD pipelines, supporting Docker containers and Kubernetes clusters, both of which are commonly used in robotics development.

4.2 Robotics-Specific Tools

Some tools/ frameworks listed below are specifically well established for use in CI/CD for robotic software development:

- ROS (Robot Operating System) https://www.ros.org/: ROS is a widely used open-source framework for building robotic applications. ROS provides tools that integrate with CI/CD pipelines, such as `rosbuild` for building packages and `rostest` for automated testing.

- Gazebo https://gazebosim.org/home: Gazebo is a powerful robot simulation environment that allows developers to test robotic software in a virtual environment before deploying it on real hardware. Simulation environments like Gazebo can be integrated with CI pipelines to simulate robot behavior and detect issues early in the development cycle.

- Docker https://www.docker.com/: Docker containers allow developers to package robotic applications along with their dependencies into a standardized unit of deployment. Docker ensures that applications are portable and can run consistently across various platforms, making it an ideal solution for CI/CD in robotics.

5. Best Practices for CI/CD in Robotics

To successfully implement CI/CD in robotics, several best practices should be followed to address the challenges discussed above.

5.1 Automate Testing with Simulation

To overcome the limitations of hardware testing, automated testing with simulations is essential. Robotics teams should focus on creating high-fidelity simulation environments that replicate real-world conditions as closely as possible. This will help identify issues early and reduce the need for physical testing.

5.2 Implement Hardware-in-the-Loop (HIL) Testing

Hardware-in-the-loop testing combines the flexibility of simulation with the accuracy of real-world testing. This allows robotic systems to be tested in an environment that closely mimics actual operations while ensuring that software changes do not negatively impact hardware performance.

5.3 Use Containerization for Deployment

Docker containers are invaluable for ensuring that robotic applications run consistently across different platforms and environments. By using Docker, teams can package their software along with its dependencies, ensuring that it can be deployed on any machine, whether it is a developer’s laptop, a testing server, or a production robot.

5.4 Establish Robust Rollback and Monitoring Systems

Given the safety-critical nature of many robotic systems, it is essential to implement rollback mechanisms and real-time monitoring to ensure that any issues in deployment can be quickly identified and addressed. Rollback systems should be carefully tested and capable of restoring robots to a stable state in case of deployment failure.

6. Case Studies of CI/CD in Robotics Applications

Next we explore different robotic applications and highlight the challenges they face in bringing CI/CD systems to fruition.

6.1 Autonomous Vehicles

The development of autonomous vehicles presents one of the most complex and safety-critical applications of robotics. Autonomous vehicles rely on a combination of software systems for perception, localization, planning, and control. These systems must operate in real-time and interact with the environment in a highly unpredictable manner, making automated testing, continuous integration, and deployment critical.

Challenges:

- Real-Time Requirements: Autonomous vehicles require real-time decision-making. CI/CD pipelines need to ensure that software changes do not introduce latency or compromise vehicle safety.

- Sensor Integration Testing: Autonomous vehicles rely on a suite of sensors (LiDAR, cameras, radar) for navigation. Ensuring that software updates do not affect sensor fusion and the vehicle’s ability to perceive its environment is critical.

- Safety and Validation: Given the safety-critical nature of autonomous driving, updates must be thoroughly tested using simulations and on-vehicle testing to ensure reliability and safety before deployment.

6.2 Collaborative Robots (Cobots)

Collaborative robots, or cobots, are designed to work alongside human operators in industrial environments. Cobots are typically used for tasks such as assembly, packaging, and material handling, where precision and adaptability are key. Manufacturers of cobots face unique challenges related to the integration of hardware and software, ensuring safety, and adapting to a variety of work environments.

Challenges:

- Safety: Since cobots work in close proximity to humans, safety is a paramount concern. CI/CD practices must ensure that any updates do not introduce risks to human operators. This involves extensive testing in simulated and real-world environments.

- Hardware Diversity: Cobots are deployed across various industries, which means they may encounter different hardware setups and operating conditions. CI/CD pipelines must account for these variations.

6.3 Industrial Robotics

Industrial robots are widely used in manufacturing for tasks such as welding, painting, and assembly. These robots often operate in environments where high precision and reliability are required. As a result, any software update must be tested thoroughly to avoid production downtime or defects in manufactured goods.

Challenges:

- Complexity of Hardware: Industrial robots can have various configurations and interfaces depending on the task at hand. Managing these configurations within a CI/CD pipeline requires customization and careful version control.

- Testing Physical Interactions: Testing robotic software in virtual environments does not always capture the full complexity of physical interactions in a manufacturing setting. Ensuring that new software updates do not negatively affect production is a major challenge.

6.4 Medical Robotics

Autonomous surgical robots are used for minimally invasive procedures that require high precision and reliability. These robots integrate complex software systems for real-time control, motion planning, and interaction with the human body. Software updates for surgical robots must undergo extensive testing to ensure patient safety and system performance.

Challenges:

- Safety Validation: Medical robots must meet stringent regulatory standards. Any update must be rigorously tested to meet FDA approval and ensure patient safety.

- Real-Time Performance: Given the critical nature of surgeries, the software must be responsive with minimal latency, which can present unique constraints in a CI/CD pipeline that automates deployment and testing.

6.5 Agricultural Robotics

In the field of agriculture, robots are increasingly being used for tasks such as autonomous harvesting, crop monitoring, and pest control. These robots must operate autonomously in unpredictable outdoor environments, making it crucial to have reliable software systems that can quickly adapt to changing conditions.

Challenges:

- Environmental Variability: Agricultural robots must function in outdoor environments, which can vary widely in terms of weather, terrain, and crop type. Testing in such dynamic conditions is complex and requires high-fidelity simulations.

- Cost of Field Testing: Physical testing of robots in the field is expensive, especially for large-scale deployments in agriculture.

7. Conclusion

Continuous Integration and Continuous Deployment are essential practices in modern software engineering, and their application to robotics has the potential to significantly improve the efficiency, reliability, and scalability of robotic systems.

However, enabling CI/CD in robotics requires overcoming unique challenges related to hardware integration, real-time systems, testing, and deployment. By leveraging appropriate tools, frameworks, and methodologies, teams can successfully implement CI/CD pipelines, improving working in parallel, reducing the time-to-market for new features, and ensuring that robots are tested rigorously and deployed efficiently.

As the field of robotics continues to evolve, the role of CI/CD in accelerating development and ensuring system reliability will become increasingly critical. Continued innovation in testing frameworks, simulation environments, and deployment strategies will help pave the way for more advanced and autonomous robotic systems, ultimately shaping the future of robotics in various industries.

From autonomous vehicles to agricultural robots, CI/CD practices have proven essential in improving development efficiency, reducing downtime, and ensuring that robotic systems are continuously improved and tested under realistic conditions.

8. References

- S. Teixeira, R. Arrais, and G. Veiga, “Cloud Simulation for Continuous Integration and Deployment in Robotics,” Jul. 2021, doi: https://doi.org/10.1109/indin45523.2021.9557476.

- D. Marijan, A. Gotlieb, and M. Kumar Ahuja, “Challenges of Testing Machine Learning Based Systems,” IEEE Xplore, Apr. 01, 2019. https://ieeexplore.ieee.org/document/8718214.

- A. Afzal, D. S. Katz, C. L. Goues, and C. S. Timperley, “A Study on the Challenges of Using Robotics Simulators for Testing,” arXiv:2004.07368 , Apr. 2020, Available: https://arxiv.org/abs/2004.07368.

- N. Koenig and A. Howard, “Design and use paradigms for gazebo, an open-source multi-robot simulator,” 2004 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS) (IEEE Cat. No.04CH37566), doi: https://doi.org/10.1109/iros.2004.1389727.

- O. Michel, “Cyberbotics Ltd. WebotsTM: Professional Mobile Robot Simulation,” International Journal of Advanced Robotic Systems, vol. 1, no. 1, p. 5, Mar. 2004, doi: https://doi.org/10.5772/5618.

- T. Sotiropoulos, H. Waeselynck, Jeremie Guiochet, and F. Ingrand, “Can Robot Navigation Bugs Be Found in Simulation? An Exploratory Study,” HAL (Le Centre pour la Communication Scientifique Directe), Jul. 2017, doi: https://doi.org/10.1109/qrs.2017.25.

- C. S. Timperley, A. Afzal, D. Katz, Jam Marcos Hernandez, and Claire Le Goues, “Crashing Simulated Planes is Cheap: Can Simulation Detect Robotics Bugs Early?,” Apr. 2018, doi: https://doi.org/10.1109/icst.2018.00040.

- C. Robert, T. Sotiropoulos, H. Waeselynck, J. Guiochet, and S. Vernhes, “The virtual lands of Oz: testing an agribot in simulation,” Empirical Software Engineering, vol. 25, no. 3, pp. 2025–2054, Feb. 2020, doi: https://doi.org/10.1007/s10664-020-09800-3.

- C. Gladisch, T. Heinz, C. Heinzemann, J. Oehlerking, Anne von Vietinghoff, and T. Pfitzer, “Experience Paper: Search-Based Testing in Automated Driving Control Applications,” Nov. 2019, doi: https://doi.org/10.1109/ase.2019.00013.

- A. Gambi, M. Mueller, and G. Fraser, “Automatically testing self-driving cars with search-based procedural content generation,” Proceedings of the 28th ACM SIGSOFT International Symposium on Software Testing and Analysis, Jul. 2019, doi: https://doi.org/10.1145/3293882.3330566.

- G. E. Mullins, P. G. Stankiewicz, and S. K. Gupta, “Automated generation of diverse and challenging scenarios for test and evaluation of autonomous vehicles,” May 2017, doi: https://doi.org/10.1109/icra.2017.7989173.

- C. E. Tuncali, T. P. Pavlic, and G. Fainekos, “Utilizing S-TaLiRo as an automatic test generation framework for autonomous vehicles,” Nov. 2016, doi: https://doi.org/10.1109/itsc.2016.7795751.

- E. Rocklage, H. Kraft, A. Karatas, and J. Seewig, “Automated scenario generation for regression testing of autonomous vehicles | IEEE Conference Publication | IEEE Xplore,” ieeexplore.ieee.org. https://ieeexplore.ieee.org/document/8317919

- A. Afzal, D. S. Katz, C. L. Goues, and C. S. Timperley, “A Study on the Challenges of Using Robotics Simulators for Testing,” Apr. 15, 2020.

- “Deploy and Manage ROS Robots with AWS IoT Greengrass 2.0 and Docker | Amazon Web Services,” Amazon Web Services, Aug. 12, 2022. https://aws.amazon.com/blogs/robotics/deploy-and-manage-ros-robots-with-aws-iot-greengrass-2-0-and-docker/

- F. Rohde, “Continuous Integration as Mandatory Puzzle Piece for the Success of Autonomous Vehicles,” SAE technical papers on CD-ROM/SAE technical paper series, Apr. 2020, doi: https://doi.org/10.4271/2020-01-0087.

- S. Teixeira, R. Arrais, and G. Veiga, “Cloud Simulation for Continuous Integration and Deployment in Robotics,” Jul. 2021, doi: https://doi.org/10.1109/indin45523.2021.9557476.

- M. Jiang, K. Miller, D. Sun, Z. Liu, and S. Mitra, “Continuous Integration and Testing for Autonomous Racing Software: An Experience Report from GRAIC,” May 24, 2021.

- L. Liu et al., “Computing Systems for Autonomous Driving: State-of-the-Art and Challenges,” IEEE Internet of Things Journal, vol. 8, no. 8, pp. 1–1, 2020, doi: https://doi.org/10.1109/jiot.2020.3043716.

- J. Iqbal, R. Xu, S. Sun, and C. Li, “Simulation of an Autonomous Mobile Robot for LiDAR-Based In-Field Phenotyping and Navigation,” Robotics, vol. 9, no. 2, p. 46, Jun. 2020, doi: https://doi.org/10.3390/robotics9020046.

- E. Yurtsever, J. Lambert, A. Carballo, and K. Takeda, “A Survey of Autonomous Driving: Common Practices and Emerging Technologies,” IEEE Access, vol. 8, pp. 58443–58469, 2020, doi: https://doi.org/10.1109/access.2020.2983149.

- L. Wang, S. Liu, H. Liu, and X. V. Wang, “Overview of Human-Robot Collaboration in Manufacturing,” Lecture Notes in Mechanical Engineering, pp. 15–58, 2020, doi: https://doi.org/10.1007/978-3-030-46212-3_2.

- R. D. Arnold, H. Yamaguchi, and T. Tanaka, “Search and rescue with autonomous flying robots through behaviour-based cooperative intelligence,” Journal of International Humanitarian Action, vol. 3, no. 1, Dec. 2018, doi: https://doi.org/10.1186/s41018-018-0045-4.

- Luiz, A. Moreira, and M. Silva, “Advances in Agriculture Robotics: A State-of-the-Art Review and Challenges Ahead,” Robotics, 2021. https://www.semanticscholar.org/paper/Advances-in-Agriculture-Robotics%3A-A-Review-and-Oliveira-Moreira/6760f97cd0ec4b721ceec96205a846e6b56f05bc

- Y. Yan, B. Zhang, J. Zhou, Y. Zhang, and X. Liu, “Real-Time Localization and Mapping Utilizing Multi-Sensor Fusion and Visual–IMU–Wheel Odometry for Agricultural Robots in Unstructured, Dynamic and GPS-Denied Greenhouse Environments,” Agronomy, vol. 12, no. 8, p. 1740, Jul. 2022, doi: https://doi.org/10.3390/agronomy12081740.

- Q. Wu, H. Chen, and B. Liu, “Path Planning of Agricultural Information Collection Robot Integrating Ant Colony Algorithm and Particle Swarm Algorithm,” IEEE Access, vol. 12, pp. 50821–50833, Jan. 2024, doi: https://doi.org/10.1109/access.2024.3385670.

- B. Van De Walker et al., “Developing a Realistic Simulation Environment for Robotics Harvesting Operations in a Vegetable Greenhouse,” Agronomy, vol. 11, no. 9, p. 1848, Sep. 2021, doi: https://doi.org/10.3390/agronomy11091848.